Το καλάθι σας είναι άδειο! Ρίξτε μια ματιά στο φανταστικό μας εμπόρευμα!

Atlas Hyper DD Ultra 2 RCA to 2 RCA Audio Cable

The latest generation Hyper DD Ultra interconnect offers a sophisticated, evenly balanced sound which draws you into the musical performance.

The conductor in the Hyper DD cable is a solid core OCC (Ohno Continuous Casting) copper core surrounded by multiple bunch-stranded ‘satellite’ conductors of high purity OCC copper, The ‘speed’ characteristic of analogue cables is determined primarily by the dielectric performance of the insulator applied around the conductor, Hyper’s conductors are encapsulated within a high-efficiency gas foamed Polyethylene dielectric, with excellent immunity to interference and noise. Termination is via Atlas' wide-band, low-mass solder-free Ultra connectors – the fewer discontinuities in the signal path, the lower the level of signal degradation and the better the performance.

Features :

- Ultra RCA Plugs

- OCC Copper Conductors

- PEF Dielectric

- Twin Twisted Pair Construction

- Dual Drain ('DD') Technology

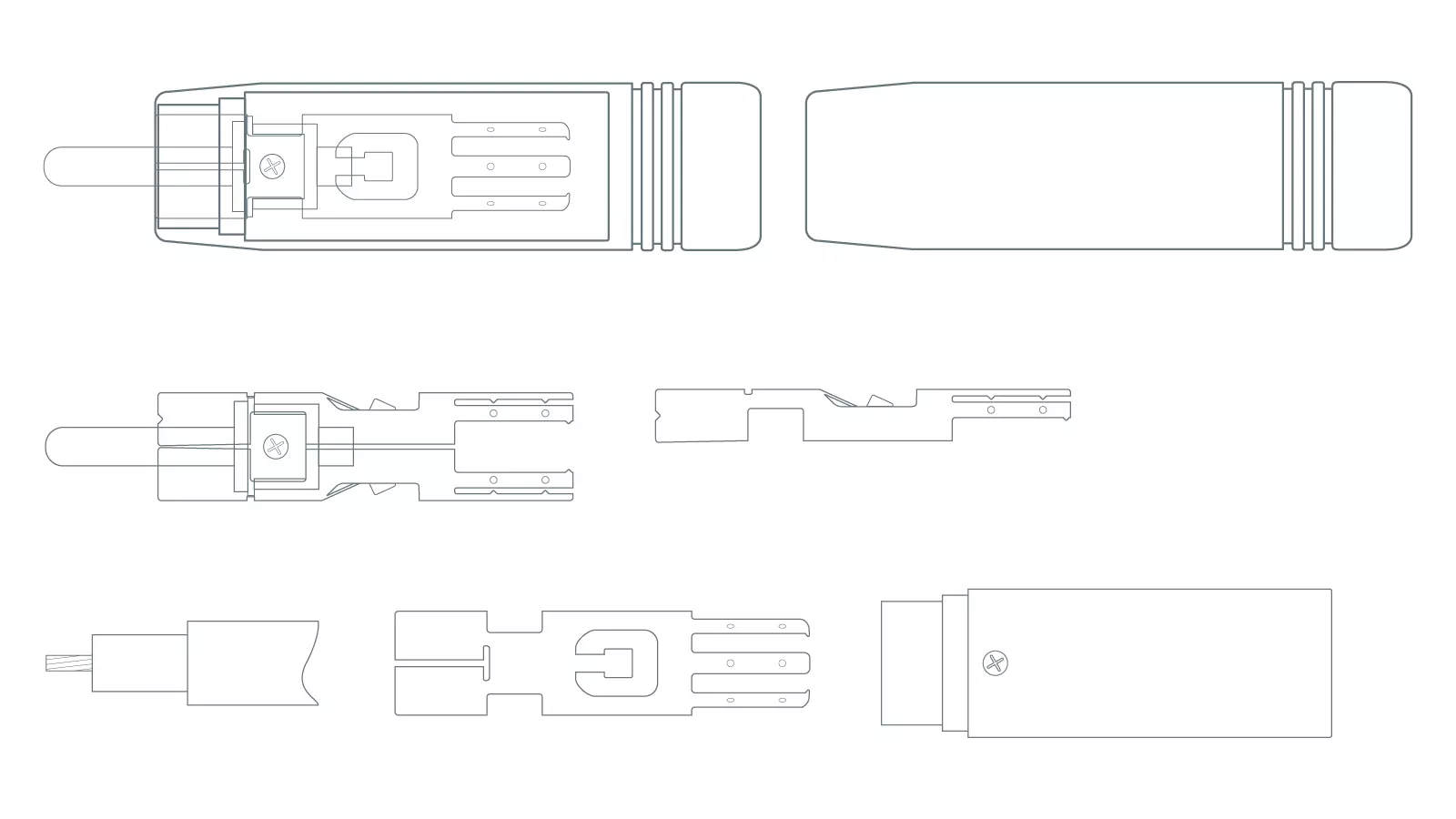

Ultra RCA Plug

The Ultra is a wide-band, OCC copper, constant impedance, self-cleaning, solder-free construction RCA plug.

In Atlas' cables, the conductor to plug interfaces are solder free, and the gold-plated conjugate brackets act as the return signal path, helping to reject RFI. Both conjugate brackets (these grip the cable without the adverse effects of compressing it, which can alter impedance) have two asymmetrical leaves which spring open on insertion and wipe clean the signal path. To maintain a clean signal path, simply remove and re-insert them periodically.

The Ultra RCA connectors utilise low-mass non-magnetic connectors to minimise the negative effect of excessive metal in the plug itself.

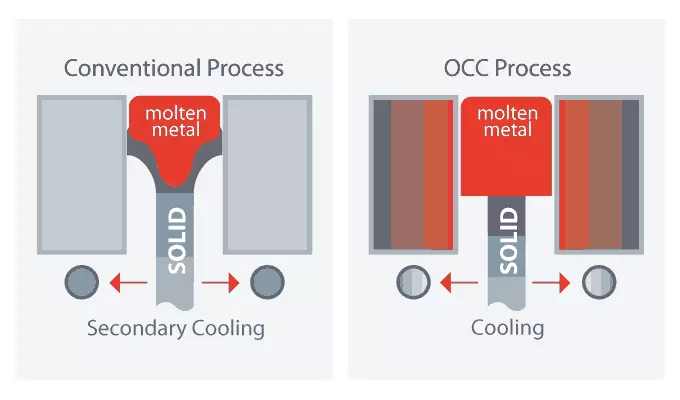

Ohno Continuous Casting Copper (OCC Copper)

The Ohno continuous casting method re-heats the extrusion as the molten copper is forced out of the mould and very slowly and gradually draws the grain or crystal down the conductor''s length, creating a ‘single crystal structure.’ Actually, because no copper is 100% pure, there will always be a few boundaries produced by impurities. The frequency of boundaries created are quite insignificant. A typical crystal in a copper conductor drawn to 0.3 mm diam. using the OCC process is 125.00 metres long!

The benefits are obvious, with almost no crystal boundaries, the audio signal is no longer impeded down the copper wire and more information and detail is delivered faithfully to the receiving equipment.

| Copper Purity Comparison (0.3mm Diameter) | ||||

| TPC | OFC | OCC | ||

| Purity | >99.9% | >99.99% | >99.999% | |

| Specific Gravity | 8.75 | 8.926 | 8.938 | |

| Gas Impurities (ppm) | ||||

| O2 | 200~500 | <10 | <5 | |

| H2 | <0.5 | <0.5 | <0.3 | |

| Average Crystal Size (Metre) | 0.007 | 0.02 | 125.00 | |

| Crystals Per Metre | 150 | 50 | 0.008 | |

PEF Dielectric

PVC (Poly Vinyl Chloride) is cheap to produce and, as such, is the most commonly used insulation in AV cables. However, PVC is the worst quality insulation a Hi-Fi or AV signal can encounter as its high loss causes a significant reduction in signal velocity. PVC is better suited to power cables and should be avoided in Hi-Fi and AV signal cables.

Other dielectrics in common use are Polyethylene, Polypropylene and Polytetrafluoride Epoxy (better known as PTFE (Teflon™) or Teflon,) and the new and unique Atlas (PTFE).

PEF (Foamed Polyethylene). The foaming process uses a blowing agent, of which there are two types. Atlas use the gas-foamed method which creates a more inert, consistent and higher quality product.

The table below shows the properties of a selection of dielectrics. Though not used as a dielectric in Atlas' cables, PVC is included for comparison purposes.

| Dielectric Material Comparison (0.3mm Diameter) | |||||

| Property | Polyvinyl Chloride (PVC) |

Foamed Polyethylene (PEF) |

Polypropylene (P.P) |

Teflon (FEP or PTFE) |

PTFE |

| Dielectric Constant (@ 50 -106Hz) |

4-8 | 2.3 | 2.25 | 2.1 | 1.3 |

| Dielectric Strength (kV mm-1) |

23-30 | 30-50 | 30-50 | 20-25 | N/A |

| Loss Tangent (% @ 50 - 106Hz) |

8-15 | 0.02-0.05 | 0.02-0.06 (@ 106Hz) |

0.02-0.07 | N/A |

| Volume Resistivity (Ohms.cm @ 20°C) |

1012-15 | >1017 | 6.5x1014 | >1016 | N/A |

| Tensile Strength (Kg mm-2) |

1.0-2.5 | 1.0-2.0 | 3.0-4.0 | 1.9-2.2 | 1.0 |

| Melting Point (°C) |

-130 | 112-120 | 155-160 | 275 | 275 |

| Max. Continuous Operating Temp. (°C) |

60 | 75 | 90 | 200 | 260 |

| Min. Operating Temp. (°C) |

-15 to -40 | <-60 | -5 to -45 | <-60 | -250 |

| Κατασκευαστές | Atlas Cables |

|---|---|

| Καλώδια | Interconnect RCA |

Ελληνικά

Ελληνικά English

English