Το καλάθι σας είναι άδειο! Ρίξτε μια ματιά στο φανταστικό μας εμπόρευμα!

Atlas Hyper Achromatic 2 RCA to 2 RCA Audio Cable

Atlas Hyper Achromatic utilises an OCC (Ohno Continous Casting) high purity copper conductor with a PEF (Foamed Polyethylene) dielectric. This design and construction combine wide bandwidth with excellent resistance to RFI (Radio Frequency Interference), which can raise noise levels, resulting in a loss of low-level detail, in a poorly shielded cable.

The Atlas Hyper uses the newly designed Achromatic RCA plugs from Atlas which deliver a solder-free, low-mass, non-conductive body, self-cleaning, recyclable RCA plug.

The end result is a natural-sounding interconnect which achieves a large open soundstage and fine levels of resolution without any sense of exaggerated ‘detail’ which is superficially impressive but quickly fatiguing to listen to.

Features:

- Achromatic RCA Plugs

- OCC Conductors

- PEF Dielectric

- Co-ax Construction

Achromatic Plugs

Atlas’s expert electro-mechanical knowledge has led to the innovation of the next generation of RCA plugs. Known as the ‘Atlas Achromatic RCA plug’, Atlas has focused on improving both performance and appearance to create a higher performance starting point for their RCA cables as well as eliminating variability in performance. This has been achieved by refocusing on materials and the assembly processes.

Atlas has made 4 key changes with the Achromatic RCA plug. Firstly, the barrel of the Achromatic plug features a high stability ABS material. This is strong, stable and of superlative surface quality.

There is also an improvement to the Achromatic plug’s contact geometry, aiding the contact properties of the plug and the self-cleaning wiping action to ensure contacts are in optimal condition and to maximise signal transmission.

The third change Atlas made was around the rifling of the RCA pin. This improvement self-aligns the conductors during the cold weld processing, ensuring a superior stable connection.

Finally, there is a reduction in the overall mass of the RCA plug by 8% which has shown to improve signal transmission.

The above changes mean a solder-free, low mass, self-cleaning, recyclable RCA plug with a non-conductive body.

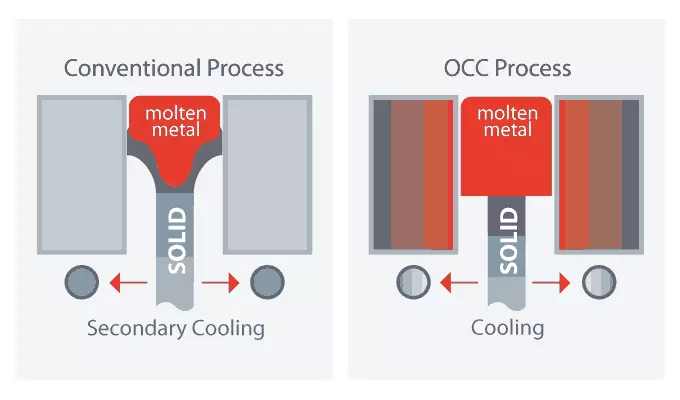

OCC Copper

The Ohno continuous casting method re-heats the extrusion as the molten copper is forced out of the mould and very slowly and gradually draws the grain or crystal down the conductor''s length, creating a ‘single crystal structure.’ Actually, because no copper is 100% pure, there will always be a few boundaries produced by impurities. The frequency of boundaries created are quite insignificant. A typical crystal in a copper conductor drawn to 0.3 mm diam. using the OCC process is 125.00 metres long! The benefits are obvious, with almost no crystal boundaries, the audio signal is no longer impeded down the copper wire and more information and detail is delivered faithfully to the receiving equipment.

|

Copper Purity Comparison (0.3mm Diameter) |

||||

| TPC | OFC | OCC | ||

| Purity | >99.9% | >99.99% | >99.999% | |

| Specific Gravity | 8.75 | 8.926 | 8.938 | |

| Gas Impurities (ppm) | ||||

| O2 | 200~500 | <10 | <5 | |

| H2 | <0.5 | <0.5 | <0.3 | |

| Average Crystal Size (Metre) | 0.007 | 0.02 | 125.00 | |

| Crystals Per Metre | 150 | 50 | 0.008 | |

PEF Dielectric

PVC (Poly Vinyl Chloride) is cheap to produce and, as such, is the most commonly used insulation in AV cables. However, PVC is the worst quality insulation a Hi-Fi or AV signal can encounter as its high loss causes a significant reduction in signal velocity. PVC is better suited to power cables and should be avoided in Hi-Fi and AV signal cables. Other dielectrics in common use are Polyethylene, Polypropylene and Polytetrafluoride Epoxy (better known as PTFE (Teflon™) or Teflon,) and the new and unique Atlas (PTFE). PEF (Foamed Polyethylene). The foaming process uses a blowing agent, of which there are two types. Atlas use the gas-foamed method which creates a more inert, consistent and higher quality product. The table below shows the properties of a selection of dielectrics. Though not used as a dielectric in Atlas' cables, PVC is included for comparison purposes.

| Dielectric Material Comparison (0.3mm Diameter) | |||||

| Property | Polyvinyl Chloride (PVC) | Foamed Polyethylene (PEF) | Polypropylene (P.P) | Teflon (FEP or PTFE) | PTFE |

| Dielectric Constant (@ 50 -106Hz) | 4-8 | 2.3 | 2.25 | 2.1 | 1.3 |

| Dielectric Strength (kV mm-1) | 23-30 | 30-50 | 30-50 | 20-25 | N/A |

| Loss Tangent (% @ 50 - 106Hz) | 8-15 | 0.02-0.05 | 0.02-0.06 (@ 106Hz) | 0.02-0.07 | N/A |

| Volume Resistivity (Ohms.cm @ 20°C) | 1012-15 | >1017 | 6.5x1014 | >1016 | N/A |

| Tensile Strength (Kg mm-2) | 1.0-2.5 | 1.0-2.0 | 3.0-4.0 | 1.9-2.2 | 1.0 |

| Melting Point (°C) | -130 | 112-120 | 155-160 | 275 | 275 |

| Max. Continuous Operating Temp. (°C) | 60 | 75 | 90 | 200 | 260 |

| Min. Operating Temp. (°C) | -15 to -40 | <-60 | -5 to -45 | <-60 | -250 |

| Κατασκευαστές | Atlas Cables |

|---|---|

| Καλώδια | Interconnect RCA |

Ελληνικά

Ελληνικά English

English